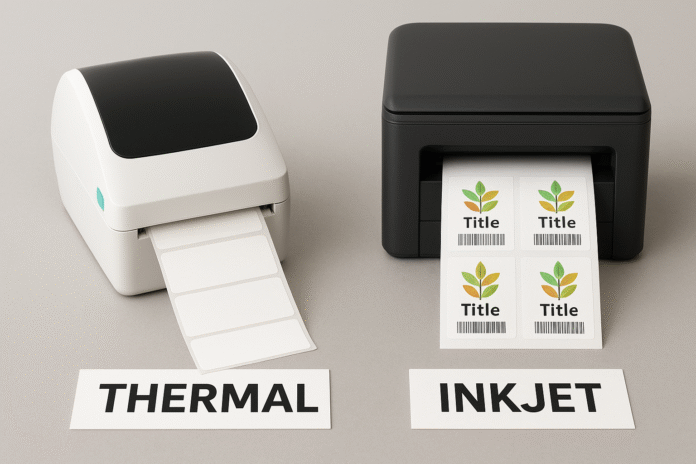

Determining the best printer technology for your business can be challenging. The debate of thermal vs inkjet labels is something both small businesses and large enterprises face when deciding how to create professional, reliable, and durable labels. Choosing the right system depends on your printing needs, your budget, and the type of labels you plan to produce.

Did you know? The way your labels are printed can directly impact your product’s shelf appeal, compliance with industry standards, and even long-term durability. That’s why it’s so important to weigh your options carefully.

Understanding Thermal Printing

Thermal printers work by applying heat to a ribbon (thermal transfer) or directly onto special heat-sensitive paper (direct thermal). This method creates sharp, smudge-resistant labels that are ideal for barcodes, shipping information, and industrial use.

- Direct thermal labels are great for short-term applications such as shipping labels.

- Thermal transfer labels use a ribbon, making them resistant to heat, sunlight, and chemicals.

This technology is widely used in warehouses, logistics companies, and healthcare settings where long-lasting, scannable labels are critical. However, when businesses require vibrant colours or custom branding, many turn to labels for inkjet printers as a complementary option to thermal printing.

The Strengths of Inkjet Printing

On the other side of the label printer comparison, inkjet printers are all about high-resolution, colorful designs. Unlike thermal printers, which focus on utility and durability, inkjet label printers excel at producing visually striking product labels.

If you sell retail products, cosmetics, beverages, or specialty foods, an inkjet printer’s flexibility and color output make it a strong choice. Inkjet printing allows for photo-quality images, gradients, and vibrant tones that elevate your brand’s presence on the shelf.

Which Is the Best Fit for You?

Deciding on the best printer for labels comes down to answering a few questions:

- Do your labels need to last in tough environments?

- Is color and brand presentation more important than durability?

- What is your monthly printing volume?

- Are you labeling products for retail shelves or shipping cartons?

For businesses that prioritize speed, durability, and lower ongoing costs, thermal printing usually comes out on top. For businesses that care about visual design, customization, and vivid color, inkjet printers are often the better option.

Pros and Cons of Thermal and Inkjet Printers

Here’s a quick breakdown of inkjet label printers compared to thermal printers:

Thermal Printers

- Durable, smudge-proof prints

- Great for barcodes and shipping labels

- High speed for bulk printing

- Limited to black or one-color ribbons (for thermal transfer)

- Not suitable for detailed, colorful graphics

Inkjet Printers

- High-resolution, full-color labels

- Perfect for product branding

- Flexible media options

- Ink costs can add up over time.

- Not as resistant to heat and chemicals

Factors to Consider Before Buying

When weighing your options, keep these points in mind:

- Volume: High-volume users often benefit from thermal printers because of lower long-term costs. They can handle thousands of labels per day without compromising speed or quality. Many businesses choose Zebra thermal label printers for this reason, as they are known for reliability in demanding, high-output environments.

- Durability: Thermal labels resist fading, while inkjet labels may fade under sunlight or chemical exposure. This makes them a trusted choice for industries like healthcare and logistics, where accurate, scannable labels are critical. In comparison, inkjet labels work well for short-term or promotional use, but thermal printing ensures longevity.

- Design: If your business needs bold, eye-catching designs, inkjet is the way to go. Inkjet technology offers vivid colours and sharp detailing that help with product branding. Thermal labels, while less colourful, are unbeatable for clarity in barcodes and compliance information.

- Environment: Industrial or warehouse settings favor thermal printing, while retail settings may lean toward inkjet. In tough conditions with heat, chemicals, or rough handling, thermal printers maintain label readability. On the other hand, inkjet labels shine in customer-facing environments where presentation and design matter most.

Exploring Modern Options

Label printers have become increasingly specialized in today’s market. Many businesses use both technologies, depending on the application. For instance, a warehouse may use an industrial thermal transfer printer for shipping labels while also having an inkjet printer on hand for custom product labels.

Additionally, if you’re considering brand-specific solutions, you’ll find popular models like the Epson inkjet label printer for high-quality color applications are known for speed and industrial durability. These choices allow you to match your equipment to the specific needs of your operation.

Conclusion

Choosing between thermal and inkjet printing ultimately depends on your business goals. If your focus is long-lasting, cost-effective labels for shipping or compliance, thermal printers are a strong choice. If your priority is high-resolution, colorful designs for retail presentation, inkjet may be the better option. In some cases, the smartest solution is a combination of both.

For businesses seeking expert guidance on how to select the right technology, the DuraFast Label Company provides a wide range of resources to help make the decision easier.

FAQs

- Are thermal printers more cost-effective than inkjet printers?

Yes. Thermal printers typically have lower long-term operating costs because they don’t rely on expensive ink cartridges.

- Do inkjet label printers support waterproof labels?

Yes, but you need compatible materials and sometimes a protective laminate to make them fully waterproof.

- Can thermal printers print in color?

Thermal transfer printers can print with different color ribbons, but they are not designed for full-color photo-quality prints like inkjets.

- Which option is faster for high-volume printing?

Thermal printers are faster and more efficient for high-volume, repetitive tasks like barcoding and shipping labels.

- Should I use one printer type or both?

Many businesses use both technologies. Thermal printers handle logistics, while inkjets manage branding and marketing labels.