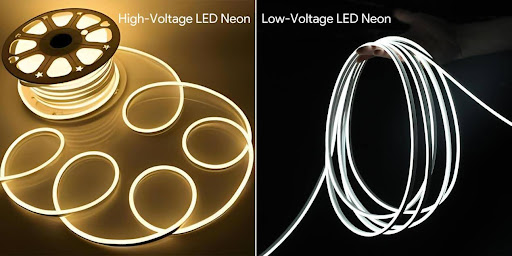

The global transition toward sustainable, flexible linear lighting has placed LED neon flex at the center of architectural and industrial design. However, for the professional procurement officer or electrical engineer, the choice between High-Voltage (110V-240V) and Low-Voltage (12V-24V) systems is fraught with technical trade-offs. This decision impacts not only the initial capital expenditure but also the long-term safety, maintenance cycles, and luminous efficacy of the installation.

To make an informed decision, one must look beyond the surface glow. This article provides an exhaustive technical analysis of the electrical architecture, thermal dynamics, and logistical considerations involved in LED strip wholesale procurement for large-scale projects.

The Electrical Foundation: Understanding Resistance and Load

At the core of the debate between high and low voltage is Ohm’s Law and the physical reality of electrical resistance in copper traces.

The Voltage Drop Phenomenon

In a low-voltage system (24V), the current required to deliver a specific wattage is significantly higher than in a high-voltage system. Because the power lost to heat is proportional to the square of the current (Ploss=I2R), low-voltage strips suffer from rapid voltage drop.

- Engineering Impact: For a 24V strip, after 5 to 10 meters, the light intensity at the tail end can drop by over 30%, leading to visible color shifting and dimness.

- Wholesale Strategy: When engaging in LED strip wholesale, buyers must check if the product uses “Constant Current ICs” (CC) rather than simple resistors. CC-equipped neon flex can extend the “no-drop” run length to 20 meters by regulating the current to each individual LED segment.

High-Voltage Efficiency

High-voltage (110V/220V) neon flex operates at much lower amperage. This allows for massive continuous runs—up to 100 meters—from a single power feed. This is the primary reason why high-voltage is the default choice for bridge lighting, skyscraper outlines, and perimeter fencing.

Safety Protocols and Regulatory Compliance

For any commercial entity, liability is a primary concern. The voltage you choose dictates the legal and safety framework of the installation.

Low-Voltage: The “Touch-Safe” Standard

12V and 24V systems are classified as Class 2 circuits. They present no risk of lethal electric shock, which simplifies the installation process.

- Application: Ideal for retail displays, hospitality interiors, and interactive art installations.

- Certification: Look for UL Listing or ETL certification when sourcing wholesale LED neon strips. These certifications ensure the transformers and the strips themselves meet rigorous fire safety standards.

High-Voltage: Industrial Rigidity

High-voltage installations are subject to the same strict codes as household wiring. They require heavy-duty insulation and, in many jurisdictions, must be installed by a licensed electrician within protective conduits.

- Critical Quality Marker: The integrity of the end-caps and joiners is the most common point of failure. Professional-grade bulk LED neon flex in the high-voltage category must feature “over-molded” or “injection-molded” connectors to prevent moisture ingress that could lead to catastrophic short circuits.

Cutting Units and Geometric Precision

The “Cutting Unit” (the distance between two points where the strip can be safely cut) determines the level of detail a designer can achieve.

- 12V/24V Precision: Low-voltage strips offer the highest resolution. Many LED strip wholesale options allow for cuts every 10mm or 25mm. This is essential for creating intricate signage, tight-radius curves, and bespoke logos where every millimeter counts.

- High-Voltage Limitations: Due to the series-wiring required for high-voltage DC conversion, the cutting units are much larger—typically 0.5 meters to 1 meter. If a project requires a 3.2-meter line, a high-voltage system may force the designer to settle for either 3 meters or 4 meters, creating significant aesthetic compromises.

Thermal Management and Material Science

Heat is the silent killer of LEDs. The higher the voltage and the longer the run, the more critical thermal dissipation becomes.

Silicone vs. PVC Encapsulation

While both materials are used in the wholesale LED neon strips market, silicone is the superior heat conductor. High-voltage strips generate internal heat through the AC-to-DC rectification process. Silicone allows this heat to dissipate into the ambient air 20% faster than PVC, preventing the internal LEDs from cooking themselves in their own jackets.

PCB Copper Thickness

The “backbone” of the neon flex is its PCB. In bulk manufacturing, many factories cut costs by using 1oz copper. For professional engineering, a 3oz copper PCB is the gold standard. It offers:

- Lower Resistance: Reducing heat and voltage drop.

- Structural Strength: Preventing the circuit from snapping during the bending and installation process.

Cost-Benefit Analysis for Wholesalers

When calculating the total cost of ownership (TCO), wholesalers must look at both the “Box Price” and the “Installed Price.”

| Expense Factor | Low-Voltage (24V) | High-Voltage (220V) |

|---|---|---|

| Product Cost per Meter | Moderate to High | Low to Moderate |

| Power Supply Density | 1 per 10m (High Cost) | 1 per 50m (Low Cost) |

| Labor Costs | Low (DIY/General Labor) | High (Licensed Electrician) |

| Safety Equipment | Minimal | Conduits, GFCI, Armored Cables |

| Maintenance | Low (Local Replacement) | Moderate (Entire Strip Failure) |

For most distributors, focusing on bulk LED neon flex in the 24V category yields higher profit margins because the value-add (drivers, dimmers, controllers) is much higher.

Advanced Control and Dimming (DMX/DALI)

Integration with modern Building Management Systems (BMS) is no longer optional for high-end projects.

- Flicker-Free Dimming: Low-voltage systems excel here. Using PWM (Pulse Width Modulation) controllers, 24V neon flex can achieve 0.1% to 100% dimming without any camera flicker—crucial for TV studios and high-end restaurants.

- Signal Integrity: High-voltage signals can sometimes interfere with data lines (EMI). When sourcing LED strip wholesale for projects requiring DMX512 or DALI control, engineers prefer low-voltage because it isolates the control signal from the high-voltage noise.

Choosing the Right Partner for Wholesale Procurement

Selecting a supplier for wholesale LED neon strips requires more than a price check. A reliable partner should provide:

- IES Files: Essential for lighting designers to simulate the light output in Dialux or Relux.

- LM-80 Reports: Evidence of the LED chips’ long-term color stability and brightness.

- Customization: The ability to provide bespoke wire exits (bottom, side, or end) to hide cabling in architectural finishes.

Conclusion: The Engineering Verdict

In 2026, the choice between high and low voltage is determined by scale and proximity. For intricate, human-scale lighting where color precision and safety are paramount, 24V is the undisputed winner. For the macro-scale illumination of the urban skyline, the efficiency of high-voltage systems is irreplaceable.

The most successful distributors and contractors are those who maintain a versatile inventory. By sourcing high-quality LED strip wholesale solutions that meet both high-voltage efficiency and low-voltage precision, you position your business at the forefront of the linear lighting revolution.

Frequently Asked Questions (FAQ)

Q: Can I use 24V neon flex for a 50-meter run?

A: Yes, but you must use a “Parallel Connection” strategy or specialized “Constant Current” strips. You cannot simply chain 50 meters of standard 24V strip together without massive voltage drop.

Q: Is silicone neon flex better for high-voltage applications?

A: Yes. Because high-voltage strips generate more heat, the superior thermal conductivity and UV resistance of silicone make it far safer and more durable than PVC.

Q: What certifications should I look for when buying bulk LED neon flex?

A: For the North American market, UL or ETL is mandatory. For Europe, look for CE, RoHS, and TUV. These ensure that the LED strip wholesale products you are importing are legal and safe.