Modern firearms enthusiasts and professional shooters are increasingly turning to red dot sights to boost their accuracy and speed up target acquisition. But here’s the thing; even the best optic won’t perform if it isn’t mounted correctly. The effectiveness of these precision devices hinges entirely on mounting solutions that deliver stability, reliability, and optimal sight alignment. Understanding your mounting options, compatibility requirements, and proper installation techniques isn’t just helpful; it’s essential for anyone serious about upgrading their firearm with a red dot sight.

Understanding Red Dot Sight Mounting Systems

Your red dot sight mounting system is the critical bridge between your optic and firearm, and it directly influences accuracy, durability, and overall performance. Think of it as the foundation of your entire setup. The mounting system needs to maintain zero under recoil, withstand environmental conditions, and hold up through repeated use, all while positioning the sight at exactly the right height for your shooting style. Different firearms demand different mounting approaches based on their design, intended purpose, and manufacturer specifications.

Optic Footprint Patterns and Compatibility

The firearms industry has created a somewhat confusing array of mounting footprint standards, which means you’ll need to pay careful attention to compatibility. Major manufacturers like Trijicon, Aimpoint, Leupold, and Holosun each use specific mounting patterns with distinct hole spacing and screw configurations, and they’re not interchangeable. Trijicon’s RMR footprint has emerged as one of the most widely adopted standards, with many firearms now coming pre-milled to accept this pattern right out of the box. Shield RMS and RMSc patterns offer more compact options that work well for smaller pistols and backup sights.

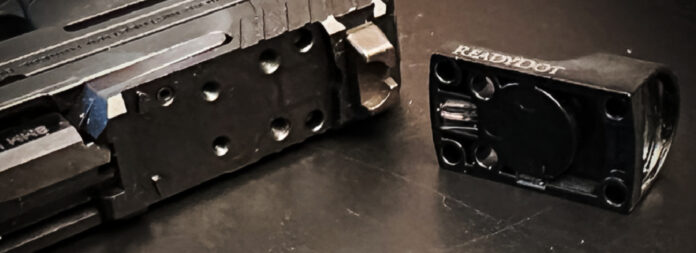

Direct Mounting Versus Adapter Plate Solutions

Firearm owners face an important choice between direct mounting and adapter plate systems when installing red dot sights. Direct mounting means attaching the optic straight to a slide or receiver that’s been specifically machined for that footprint pattern. This approach offers the lowest profile possible, potentially better durability, and eliminates an additional interface that could introduce minor alignment variations. Many newer production firearms arrive from the factory with pre-milled slides designed for specific optic patterns, making direct mounting straightforward and cost-effective. However, direct mounting does limit your flexibility if you want to switch between different optics with incompatible footprints down the line. For professionals who need to test multiple optics or adapt to different footprint standards, red dot adapter plates provide a versatile alternative that allows shooters to mount various optic footprints on firearms not originally designed for them. These plates function as intermediary mounting surfaces that convert one footprint pattern to another, significantly expanding your compatibility options. Quality adapter plates are precision-machined from durable materials to maintain zero and withstand recoil forces without compromise. The minimal height increase from adapter plates is often negligible for most shooting applications, while the flexibility they provide can be invaluable for anyone who wants to test different optics or prepare for future upgrades.

Installation Best Practices and Considerations

Proper installation of red dot sights demands attention to detail, the right tools, and strict adherence to manufacturer specifications to ensure both safety and performance. Start by thoroughly cleaning all mounting surfaces to remove any oils, debris, or protective coatings that could compromise the interface; this step isn’t optional. Use a quality degreasing agent and make sure surfaces are completely dry before moving forward with installation. Thread preparation is absolutely critical here. Applying a small amount of medium-strength thread locker to mounting screws prevents loosening under recoil while still allowing future removal when needed.

Height Considerations and Co-Witness Options

The mounting height of your red dot sight dramatically affects your sight picture, cheek weld, and the ability to co-witness with iron sights; it’s more important than many shooters realize. Lower mounting positions generally provide better ergonomics for traditional shooting stances and maintain consistency with trained muscle memory. That said, some applications actually benefit from elevated mounts that allow easier viewing while using protective equipment, night vision devices, or maintaining heads-up awareness in tactical situations. Co-witness capability refers to the relationship between your red dot and backup iron sights, and there are three primary options to consider.

Maintaining Your Red Dot Mounting System

The long-term reliability of red dot mounting systems depends on regular maintenance and periodic inspection to catch potential issues before they affect your performance. Establish a maintenance schedule that includes checking mounting screw tightness at regular intervals, particularly after extended shooting sessions or exposure to harsh environmental conditions, don’t wait until something feels wrong. Vibration from repeated firing, temperature fluctuations, and physical impacts can gradually loosen even properly installed mounting hardware over time. Inspect mounting surfaces regularly for signs of wear, erosion, or damage that could compromise the interface integrity.

Conclusion

Selecting and properly implementing red dot mounting solutions represents a critical decision that directly impacts your shooting performance, equipment reliability, and overall satisfaction with your firearms setup. Understanding the various mounting options, footprint compatibility requirements, and installation best practices empowers you to make informed choices that genuinely suit your specific needs. Whether you opt for direct mounting or adapter plate solutions, prioritizing quality components and proper installation techniques ensures your red dot sight remains securely attached and accurately aligned throughout its service life. Regular maintenance and periodic inspection of your mounting system prevents potential failures and maintains the precision that red dot sights are designed to deliver.