A Multilayer PCB Board is the backbone of modern electronic systems that require high circuit density, compact size, and reliable performance. As electronic devices become more powerful and smaller in size, traditional single-sided or double-sided boards are no longer sufficient. Multilayer technology enables designers to integrate complex circuits within a compact footprint while maintaining signal integrity and performance.

From telecommunications infrastructure and medical equipment to industrial automation and automotive electronics, multilayer boards play a crucial role in advanced applications. Selecting the right Multilayer PCB board manufacturer is essential to ensure consistent quality, precise fabrication, and long-term reliability.

What Is a Multilayer PCB Board?

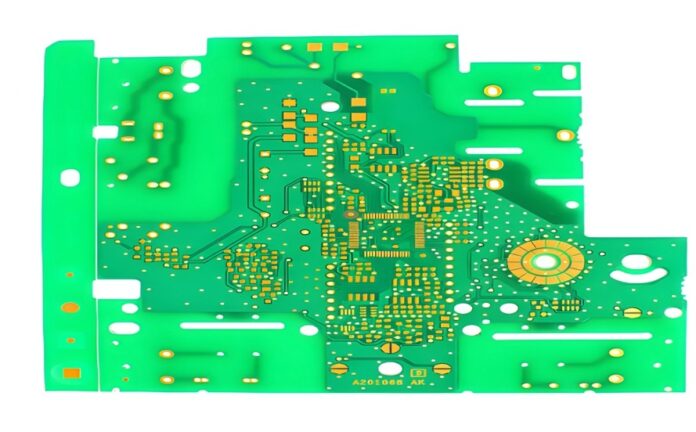

A Multilayer PCB Board is a printed circuit board composed of three or more layers of conductive copper separated by insulating materials. These layers are laminated together under heat and pressure to form a single, unified structure.

Unlike single-sided boards that have copper on only one side or double-sided boards that have copper on both sides, multilayer boards stack multiple conductive layers internally. These internal layers are connected using plated through-holes or microvias, allowing complex signal routing within limited space.

Multilayer PCB Boards typically range from four layers to more than twenty layers, depending on the complexity of the application. High-end computing and telecommunications systems may use boards with very high layer counts to support dense routing and power distribution requirements.

Structure of a Multilayer PCB Board

The structure of a Multilayer PCB Board consists of alternating layers of copper foil and insulating material, usually prepreg and core laminates. The core provides structural stability, while prepreg layers bond the stack together during lamination.

Signal layers carry electrical traces, while dedicated power and ground planes help distribute voltage evenly and reduce electromagnetic interference. This layered approach improves electrical performance and enhances signal integrity in high-speed circuits.

Proper stack-up design is critical in multilayer boards. The arrangement of signal, ground, and power layers affects impedance control, noise reduction, and thermal management. A professional Multilayer PCB board manufacturer provides design guidance to optimize layer configuration for performance and manufacturability.

Advantages of Multilayer PCB Board

One of the primary advantages of a Multilayer PCB Board is its ability to support complex circuitry in a compact size. By stacking multiple layers, designers can route more signals without increasing board dimensions.

Signal integrity is significantly improved because internal ground and power planes reduce noise and crosstalk. This makes multilayer boards ideal for high-speed digital and RF applications.

Mechanical strength is another advantage. The laminated structure provides enhanced rigidity compared to single or double-sided boards. Multilayer boards also offer improved reliability since fewer external connectors are needed.

Additionally, multilayer designs allow better thermal management. Dedicated copper planes can help distribute heat evenly across the board, improving overall system stability.

Manufacturing Process of Multilayer PCB Board

The production of a Multilayer PCB Board involves several precise steps to ensure structural integrity and electrical reliability.

The process begins with PCB design and preparation of manufacturing files. Inner layers are imaged and etched first to create circuit patterns. After inspection, these inner layers are stacked with prepreg sheets and copper foils according to the specified layer configuration.

The stack is then laminated under controlled heat and pressure to bond all layers into a solid board. Once laminated, drilling machines create holes for vias and through-hole components. These holes are plated with copper to establish electrical connections between layers.

Outer layers are imaged and etched to complete the circuit routing. A solder mask layer is applied to protect copper traces from oxidation and prevent short circuits. Surface finishes such as HASL, ENIG, or immersion silver are applied to ensure solderability.

Finally, electrical testing verifies connectivity and ensures there are no open circuits or shorts. Because multilayer boards are complex, working with an experienced Multilayer PCB board manufacturer is essential to maintain tight tolerances and high yields.

Applications of Multilayer PCB Board

Multilayer PCB Boards are widely used in industries that demand compact and high-performance electronics.

In telecommunications, they support routers, switches, and base stations that require high-speed data transmission. In medical equipment, multilayer boards are used in imaging systems, monitoring devices, and diagnostic tools where reliability is critical.

Automotive electronics rely on multilayer technology for advanced driver-assistance systems, infotainment modules, and control units. Industrial automation systems use multilayer boards in programmable logic controllers and motor drives.

Consumer electronics such as laptops, gaming consoles, and smart devices also depend on multilayer designs to achieve compact form factors and advanced functionality.

Challenges in Multilayer PCB Board Production

Despite their advantages, Multilayer PCB Boards present manufacturing challenges. As layer counts increase, maintaining precise alignment during lamination becomes more complex. Any misalignment can affect signal routing and board reliability.

Thermal expansion must be carefully managed to prevent delamination or warping. High-speed designs require controlled impedance, which demands strict control over trace width, spacing, and dielectric thickness.

Testing multilayer boards is also more demanding due to the complexity of internal connections. This highlights the importance of partnering with a qualified Multilayer PCB board manufacturer that has advanced equipment and quality control systems.

How to Choose the Right Multilayer PCB Board Manufacturer

Selecting the right Multilayer PCB board manufacturer is critical for achieving consistent performance and minimizing production risks.

A reliable manufacturer should have experience producing high-layer-count boards and handling complex stack-ups. Advanced lamination equipment and precision drilling systems are essential for maintaining tight tolerances.

Quality assurance processes such as automated optical inspection, X-ray inspection, and electrical testing ensure that each board meets design specifications. Certifications and compliance with international standards indicate a strong commitment to quality.

Technical support is another key factor. An experienced Multilayer PCB board manufacturer provides design for manufacturability feedback to optimize layer configuration, reduce costs, and improve yields.

Production scalability is also important. Whether you need prototype development or large-scale manufacturing, your supplier should be able to meet demand without compromising quality.

Future Trends in Multilayer PCB Board Technology

As technology advances, Multilayer PCB Boards are becoming more sophisticated. Higher layer counts, finer trace geometries, and improved materials are enabling faster data speeds and greater integration.

The rise of 5G, artificial intelligence, and electric vehicles is driving demand for high-performance multilayer designs. Advanced manufacturing technologies such as automated optical inspection and smart process control are improving consistency and efficiency.

Environmental sustainability is also influencing production methods, with manufacturers adopting eco-friendly materials and lead-free processes.

Conclusion

A Multilayer PCB Board is essential for modern electronics that require high circuit density, compact design, and reliable performance. By stacking multiple conductive layers, these boards enable advanced routing, improved signal integrity, and enhanced mechanical strength.

Because of their complexity, choosing an experienced Multilayer PCB board manufacturer is crucial. The right partner ensures precision fabrication, strict quality control, and scalable production capacity.

Whether for telecommunications, medical devices, automotive systems, or consumer electronics, collaborating with a trusted Multilayer PCB board manufacturer will help you achieve superior performance, long-term reliability, and competitive advantage in today’s fast-evolving electronics industry.